Rotor

At the heart of the Wallenstein based BX Chipper is an oversize heavy duty rotor and reversible chipping blades. The large diameter rotor has a faster tip speed for improved chipping action and the heavy gauge steel keeps your momentum to power through 7″ diameter branch or 6.5 x 12″ slabs.

Blades

The reversible blades are precision cut tool steel and hardened, keeping a sharp cutting edge and maximizing the performance of the chipper.

Twig Breaker Blower Paddles

Behind the blades are blower paddles with integrated dual twig breakers designed for greater output force and smaller chips exiting the machine. This provides more consistent chip size and allows you to propel the chips further.

Adjustable Chute

Easily control where you want the chips with the double adjustable exit chute. The chute swivels 270 degrees (facing operator is blocked) and the top deflector adjusts the distance.

Hydraulic Feed Hopper with Speed Control and Forward or Reverse

Maximize your chipping with the aggressive hydraulic feed hopper. Chipping becomes effortless when you let the rotating teeth do all the work. As the brush is fed into the chipper, you can be ready with the next piece.

Driveline is included.

Powered by: Feed is:

Tractor PTO Hydraulic Feed

25-45 HP

Optional parts:no stress control system,long tail

Feature--BX62RS

Uses:

Perfect for those clean-ups after a storm,pruning or just processing general gardening wastes

Creating mulch for garden plants and trees for conserving water

Feature:

The BX-62RS is a first-class wood chipper. Working with this unit is a true delight thanks to its hydraulic feed system. With this model, feeding and pushing etc. are a thing of the past; the 2 large feed rollers take care of this themselves. The speed of the feed rollers can be continuously adjusted. This is important so that the feed speed can be adjusted to fit the diameter of the material to be shredded. Smaller diameters can be fed faster than larger diameters. In the event that the feeder should become blocke,d the feed can be set into reverse using the large handle on the hopper. Furthermore, the feed can be switched off using this handle. The unit is powered via the tractor’s hydraulics; a pressurised supply line and an unpressurised return line are required or alternatively a double-acting control unit is required.

As of immediately we deliver the newest version of the BX-62 - the BX-62 RS, which has double-sided mounting of the feed rollers and a strengthened feed hopper. There are similar versions of this shredder, some of which offered at lower prices, which do not have this strengthening. This can lead to bending the feed rollers and bearing damage, as these are only mounted on one side; the other side of the feed rollers hangs freely. Some competitors also advertise their shredders as BX-62 although they are talking about different types. Please make sure you check competing offers carefully.

The wood chipper comes delivered complete with P.T.O. A shear pin has also been built into one side of the P.T.O., which is a safety precaution as it serves as a predetermined breaking point in the event of blockages or overloading. This means that even larger tractors with more than 100 HP can be used with no problem. You should have an engine power output of at least 30 HP. The P.T.O. must have a speed of 540 rpm.

The feed hopper has an opening of 63.5 x 63.5 cm; at the bottom the opening measures 16.5 x 30.5 cm. A maximum diameter of 16.5 cm can be shredded. Many competitors list the maximum shredding diameter as the measurement of the bottom of the feed hopper, however, this value is unrealistic and can trigger the safety mechanism in the P.T.O. Softer woods with a width up to 25 cm can be shredde,d although such diameters are usually processed to firewood and not chipped.

The BX-62RS has a very sturdy finish! The material strength of the sheet metal in the weight-bearing area are 10 and 12 mm. At the hopper and the non-weight-bearing parts it is between 4 and 6 mm.

Compare these values with competing models because this is one of the areas they like to save on! The hopper can be folded upward with ease for transport and is secured using a cotter pin. In order to make folding upward easier, the chipper has 2 shock absorbers. The unit has been constructed in a very maintenance-friendly way; you can open the flywheel cover completely by unscrewing just one screw, giving you access to the 4 cutting blades. These cutting blades are double-side,d so that they can be turned around if required. The flywheel has a net-weight of 95 kg and has fitted wings, which produces the incredibly powerful suction which ultimately expels the chippings out of the chute. Thanks to this powerful suction, a blockage of the shredding unit is virtually impossible.

The chute has a height of 220 cm (plus the height of the lower link) and can be rotated 360 degrees. We are also able to additionally deliver a 50 cm chute extension upon request. This enables easy direction of the chippings onto a tractor trailer or directly into Big Bags. The ejection angle can also be changed. The BX-62RS can expel the chippings up to 10 m.

The shredder has been conceived to be attached to 3 point linkage and can be used from Cat. I.

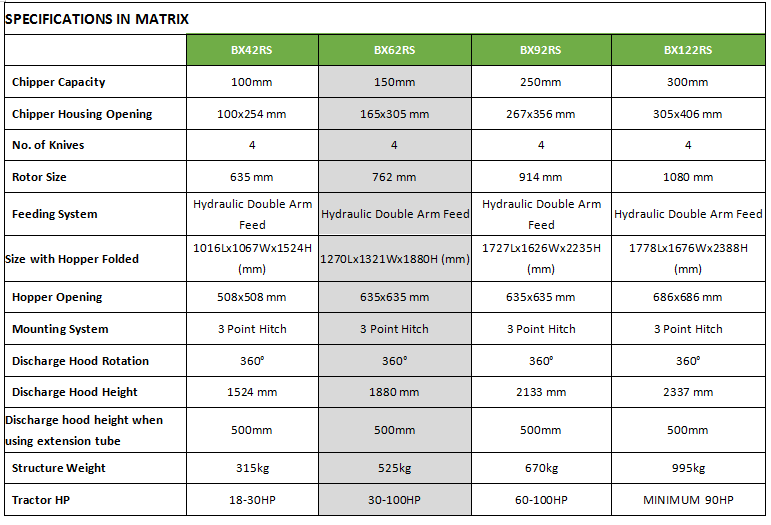

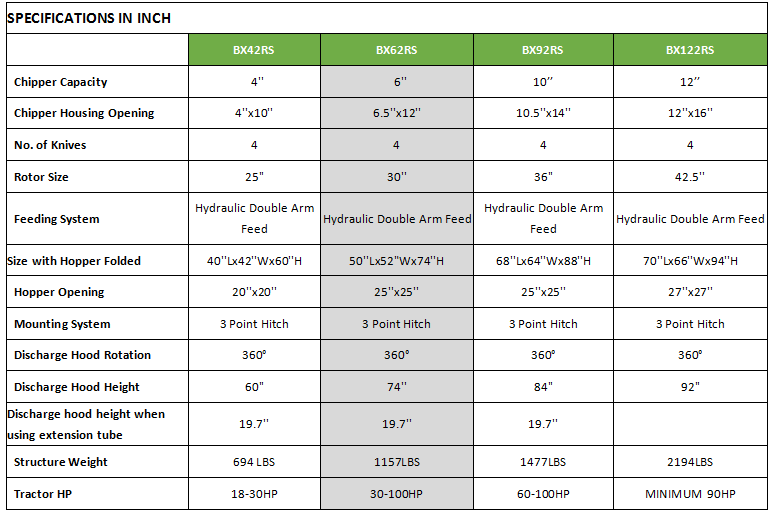

Technica data

• For 30-100 HP tractors (22-74 kW)

• Disk-operated chipper

• Hydraulic transmission with double rollers

• Wood feeding control with rollers double rotation:clockwise and counterclockwise

• Automatic stop of power supply for safety

• Intake pipe with 360° double adjustment

• 4 knives + counterknife

• Flow regulator

• Maximum material diameter: 13 cm